Business Socks Manufacturer from China

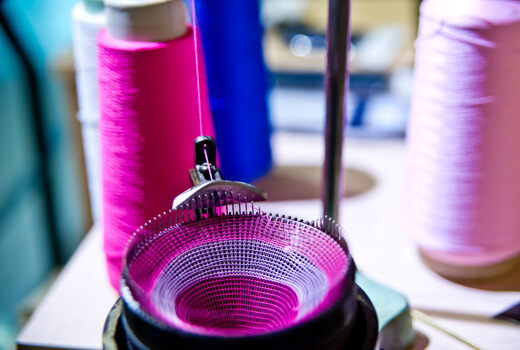

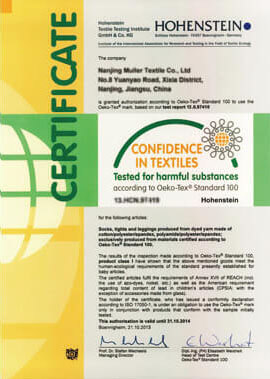

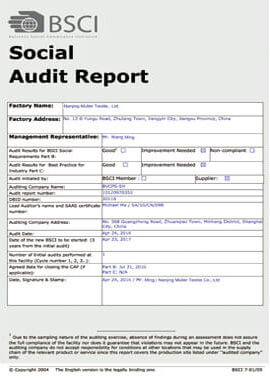

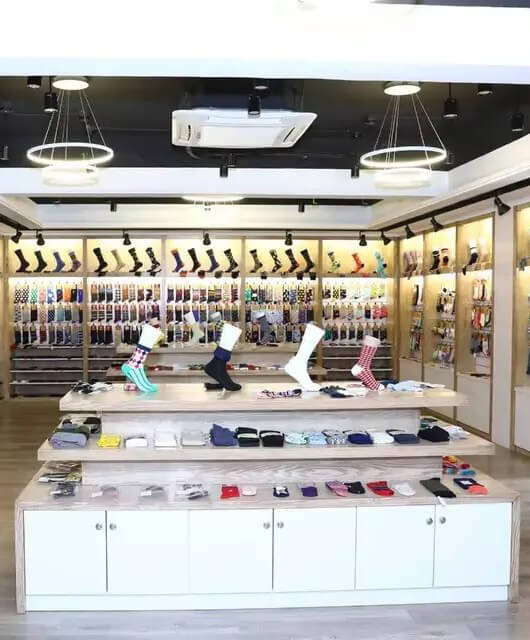

Muller Natural Socks is a leading business socks manufacturer from China, dedicated to producing high-quality, comfortable, and stylish socks for professionals around the world. With over a decade of experience in the textile industry, we have established ourselves as a trusted supplier of premium business socks for global brands, retailers, and wholesalers. Our extensive manufacturing capabilities, strict quality control, and commitment to innovation make us the ideal partner for your business socks needs. Our advanced production capabilities include gauges ranging from 3.5″ to 4.5″ and needles from 108n to 144n, ensuring a perfect balance of softness, comfort, and performance in every pair.

Connect with Us!

If you are looking for a reliable business socks manufacturer from China, Muller Natural Socks is your best choice. Contact us today to discuss your requirements, request samples, or get a quote for your next order. Join hands with Muller Natural Socks and let’s create high-quality business socks that enhance style, comfort, and performance for professionals worldwide!