Merino Wool Socks Manufacturer from China

In the world of high-performance and comfortable socks, merino wool socks stand out as a top choice for outdoor enthusiasts, athletes, and everyday users. If you are looking for a merino wool socks manufacturer from China, you need a reliable partner who not only provides quality products but also ensures cost-effectiveness, sustainability, and a seamless production process.

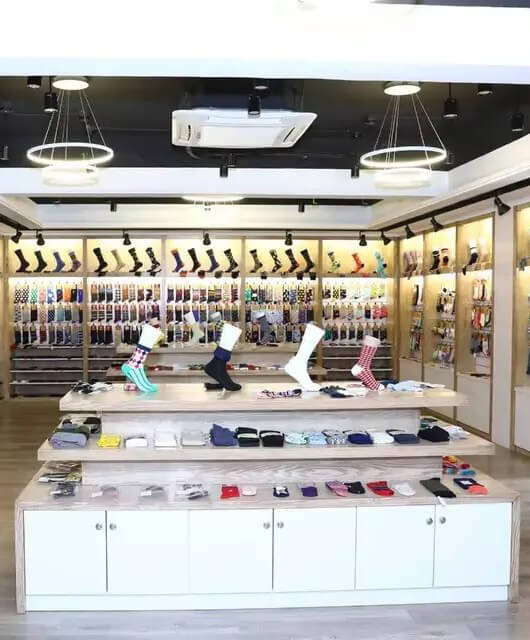

At Muller Natural Socks, we specialize in manufacturing and supplying high-quality merino wool socks for brands, retailers, and distributors worldwide. With advanced production facilities, cutting-edge technology, and a commitment to ethical sourcing, we have built a solid reputation as a trusted merino wool socks manufacturer from China.

Main Products

We cater to various markets, producing specialized merino wool socks for different activities and purposes:

» Merino Wool Hiking Socks: designed for rugged outdoor adventures, these socks feature with cushioned soles for impact absorption, moisture-wicking properties to keep feet dry, seamless toes to prevent blisters.

» Merino Wool Running Socks: our running socks provide lightweight design with breathable mesh zones, compression support for improved circulation, reinforced heel and toe for durability.

» Merino Wool Skiing Socks: perfect for winter sports, these socks offer over-the-calf length for warmth, temperature regulation to prevent overheating, elastic arch support for comfort.

» Merino Wool Cycling Socks: for professional and casual cyclists, we manufacture thin and breathable fabric for ventilation, seamless construction to reduce friction, compression fit to enhance endurance.

» Merino Wool Everyday Socks: ideal for daily wear, these socks feature with stylish designs and color variations, odor-resistant merino wool for freshness, soft and comfortable texture for all-day wear.

1.Design

| Serial | Plan | Content |

|---|---|---|

| 1 | Referencing Existing Samples | Analysing previous designs helps refine structural features and enhance comfort. |

| 2 | Custom Vector Graphic Design | Using Adobe Illustrator or CorelDRAW, we assist clients in designing stylish, high-performance socks that match consumer preferences. |

Whether you refer to existing samples or design your own using vector graphics software, you need to communicate closely with the manufacturer to make necessary adjustments to ensure that the final product meets design expectations and quality standards.

»Referencing Existing Samples: Analysing previous designs helps refine structural features and enhance comfort.

»Custom Vector Graphic Design: Using Adobe Illustrator or CorelDRAW, we assist clients in designing stylish, high-performance socks that match consumer preferences.

2.Negotiation

We offer flexible options to meet various style and performance requirements:

| Serial | Items | All Parameters |

|---|---|---|

| 1 | Yarn Count | 21s and 32s. |

| 2 | Feeding Mode | Single-sided, double-sided, concave-convex. |

| 3 | Jacquard Pattern | Stripes, plaids, floral designs, and custom patterns tailored to the Australian market. |

»Yarn Count: 21s and 32s.

»Knitting Techniques: Single-sided, double-sided, concave-convex.

»Jacquard Pattern Options: Stripes, plaids, floral designs, ect.

3.Sampling

Before production, we create a technical sheet that contains are the information to produce the desired socks. Sample pairs are produced and sent to client for quality, size, color, drawings and other elements confirmation. We only start production when the samples are approved. If required we can perform test reports.

Regarding the sampling of socks, we will pay attention to the following aspects:

| Serial | Attention | Content |

|---|---|---|

| 1 | Grind the Achilles Tendon | When running, sports socks use Achilles tendon anti-wear pads, which can effectively prevent high-frequency friction between the Achilles tendon and sports shoes. |

| 2 | Grind the Soles | For flat feet, small terry tissue is used instead of flat tissue, which increases the cushioning when walking and makes it no longer easy to wear the soles of the feet. |

| 3 | Sock Soles Slippery | We add a ring of elastic with appropriate elasticity to the arch of the foot to prevent the socks from slipping when walking or exercising and enhance stability. |

| 4 | Easy to Slip Off | The sock cuffs are made of rubber bands with high-quality lifting strength and elasticity, which will prevent them from slipping or pinching your ankles. If it is a single-layer sock, you can apply a layer of non-slip silicone inside the sock opening as needed. |

| 5 | Poor Elasticity | Use good quality spandex to enhance the elasticity of the socks. |

| 6 | Easy to Break Holes | Sock toes, soles, heels and other areas prone to holes are reinforced with high-quality nylon yarn to enhance firmness. |

| 7 | Thick Toe Seams | A sewing worker with more than 10 years of experience will make the sock toe close to seamless if computerized sewing is used; if eye-stitching is used, the sock toe will be smooth and seamless. |

| 8 | Seams Open Easily | The use of high-quality nylon yarn as the suture line at the sock toe and ankle seams can increase the firmness of the seams, and at the same time, no tiny openings are missed when the sock toe is sewn. |

» Grind the Achilles Tendon: When running, sports socks use Achilles tendon anti-wear pads, which can effectively prevent high-frequency friction between the Achilles tendon and sports shoes.

» Grind the Soles: For flat feet, small terry tissue is used instead of flat tissue, which increases the cushioning when walking and makes it no longer easy to wear the soles of the feet.

» Sock Soles Slippery: We add a ring of elastic with appropriate elasticity to the arch of the foot to prevent the socks from slipping when walking or exercising and enhance stability.

» Easy to Slip Off: The sock cuffs are made of rubber bands with high-quality lifting strength and elasticity, which will prevent them from slipping or pinching your ankles. If it is a single-layer sock, you can apply a layer of non-slip silicone inside the sock opening as needed.

» Poor Elasticity: Use good quality spandex to enhance the elasticity of the socks.

» Easy to Break Holes: Sock toes, soles, heels and other areas prone to holes are reinforced with high-quality nylon yarn to enhance firmness.

» Thick Toe Seams: A sewing worker with more than 10 years of experience will make the sock toe close to seamless if computerized sewing is used; if eye-stitching is used, the sock toe will be smooth and seamless.

» Seams Open Easily: The use of high-quality nylon yarn as the suture line at the sock toe and ankle seams can increase the firmness of the seams, and at the same time, no tiny openings are missed when the sock toe is sewn.

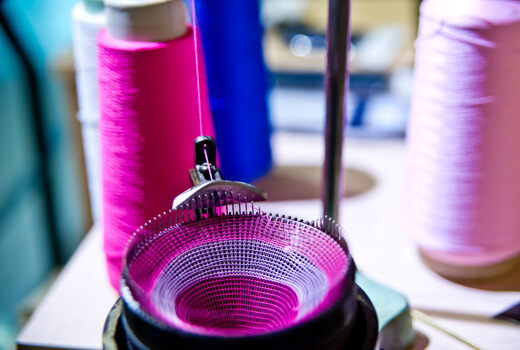

4.Knitting

After the sample is confirmed, we produce the order as per the established specifications and requirements. At present, we have 6 skilled mechanics, 30 experienced knitters, and 80 computerized sock machines. The sock machines are equipped with single and double syringes of different gauges and needles.

| Serial | Types | Gauges | Needles | Jacquard |

|---|---|---|---|---|

| 1 | Single Syringe | 3.5, 4.0 4.5 inches | 108, 120, 132, 144, 168, 176, 200 | Single-sided colored jacquard |

| 2 | Double Syringe | 4.0,4.5 inches | 108, 120, 144, 168, 200 | Double-sided colored jacquard, concave-convex jacquard |

» Single Syringe Machines: 3.5–4.5 gauges, 108–200 needles, single-sided colored jacquard.

» Double Syringe Machines: 4.0–4.5 gauges, 108–200 needles, double-sided jacquard, and textured patterns.

5.Linking

Toes Linking mainly uses two methods to link the head, such as manual cross-stitching.

» Straight Blind Stitching: This method uses a straight sewing machine, uses overlock stitching, and wraps the sock toe coil with stitches to produce a relatively flat sock toe.

» Manual Cross-Stitching: This method uses a round socks machine, and the stitched socks toe coils are sequentially put on the needle of the sewing machine to sew. The socks toe produced has no ribs.

6.Boarding

Before packaging, we use electric steam boarding machines to ensure each pair of socks maintains its shape and appearance.

» Rotary Electric Steam Boarding: Ideal for setting short socks.

» Hanging Electric Steam Boarding: Suitable for all all types of socks.

7.Inspection

Quality inspection takes placed in every step of the production process and the most thorough product quality inspection takes placed right before packaging in order to guarantee that no socks are defective or contaminated. Quality inspections can be arranged with external entities.

| Serial | Lists | Content |

| 1 | Deal with the Excess Threads Inside the Socks | Use small, sharp scissors to make clean cuts close to the sock’s surface without cutting into the sock itself. This reduces the chance of threads catching or tangling during wear. |

| 2 | Check the Lengths and Holes of Socks | Lay each sock flat on a measuring board or next to a ruler, in a relaxed position with no stretch or compression, making sure the heel and toe are properly aligned. Pay attention to seams and joins, which are common locations for holes to develop due to stitching failure. |

| 3 | Formaldehyde Content | Class A products ≤ 20mg/kg, which refer to products used by infants and young children.Class B products ≤ 75mg/kg, which refer to products that come into direct contact with the skin when worn. |

| 4 | Ph Value | 4.0-7.5, it can be understood that Class A and Class B products should be in this range (there are no Class C products in socks). |

| 5 | Bad Smell | None. There should be no smell in finished socks. |

| 6 | Decomposable Aromatic Amine Dye | Disable. Some dyes are harmful to the human body and even cause canceration, such as azo dyes, the standard stipulates that the use of these dyes should be prohibited, and the detection limit should be ≤ 20mg/kg. |

| 7 | Color Fastness to Water | It refers to the change of color fastness of socks after exposure to water. According to the test of discoloration and staining, class A products ≥ grade 4, class B products ≥ grade 3. |

| 8 | Color Fastness to Acid and Alkali Perspiration | The change of color fastness of socks in the presence of acidic or alkaline sweat can be divided into discoloration and staining tests, class A products ≥ grade 4, class B products ≥ grade 3. |

| 9 | Color Fastness to Dry Friction | The change of color fastness of socks under the condition of non-wetting and friction at room temperature: class A ≥ grade 4, class B ≥ grade. |

| 10 | Color Fastness to Saliva | It refers to the change of color fastness of socks when they encounter saliva. Divided into discoloration and staining test, Class A products ≥ grade 4, Class B products are not tested. |

8.Packaging

After passing quality inspection, it will be packaged according to customized requirements. At present, there are packaging cardboard, cardboard bags, cartons and other types of packaging. It involves packaging materials such as packaging cardboard, cardboard bags, cuff labels, size stickers, sock hangers (paper cards), waist seals, packaging hooks, sock toe/cuff fasteners, outer packaging cartons and other packaging materials.

9.Delivery

Choose the appropriate freight method, prepare and review all required export documents, such as commercial invoice, packing list, certificate of origin, etc., comply with relevant international trade regulations and standards, and ensure smooth customs clearance procedures in the destination country in cooperation with logistics partners.

Private Label & OEM Service

Looking to create custom merino wool socks for your brand? We provide full customization options, including:

» Material Composition: 100% merino wool or blended with nylon/spandex for durability.

» Sock Length: Ankle, crew, knee-high, or over-the-calf.

» Colors & Patterns: Custom dyeing with Pantone color matching.

» Branding: Embroidered or printed logos, custom packaging.

» Special Features: Anti-slip grips, reinforced toe/heel, extra cushioning.

Whether you’re launching a new sock brand or expanding your product line, we can help bring your vision to life.

Why Choose Us?

When selecting a manufacturer, it’s essential to consider factors like material quality, production expertise, customization options, and pricing. Here’s why we are your best choice:

» Premium Quality Merino Wool Socks: We use high-quality merino wool sourced from the finest wool suppliers. Our socks are known for their softness, breathability, durability, and moisture-wicking properties. Merino wool is naturally odor-resistant, making it perfect for outdoor activities and extended wear.

» Customization to Suit Your Brand Needs: We offer full OEM & ODM services to meet your unique requirements. Whether you need hiking socks, running socks, skiing socks, cycling socks, or casual wool socks, we can tailor the design, fabric composition, and features to match your brand identity.

» Advanced Manufacturing Technology: Our factory is equipped with Lonati knitting machines from Italy, ensuring precision, seamless construction, and high efficiency. We produce high-density and fine-knit socks with reinforced toes and heels for enhanced durability.

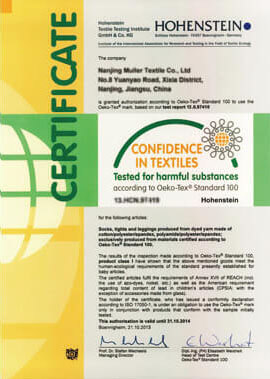

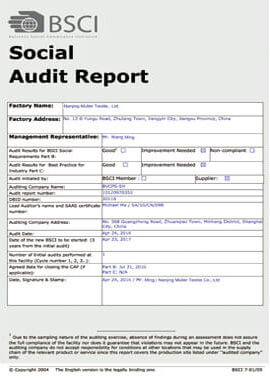

» Sustainable and Ethical Production: We adhere to Responsible Wool Standards (RWS), ensuring that our merino wool is ethically sourced. Additionally, we practice environmentally friendly manufacturing, using non-toxic dyes and FSC-certified packaging.

» Competitive Pricing & Bulk Orders: As a leading merino wool socks manufacturer from China, we provide wholesale pricing, allowing you to scale your business with cost-effective solutions. Whether you need small batches or mass production, we can meet your demands.

» Fast and Reliable Shipping: Thanks to our efficient logistics network, we guarantee on-time delivery to clients worldwide. We offer multiple shipping options, including express (FedEx, DHL, UPS), air freight, and sea shipping, based on your requirements.

Our Certification

Connect with Us!

If you’re looking for a trusted merino wool socks manufacturer from China, Muller Natural Socks is here to provide high-quality, customizable, and cost-effective solutions. Whether you’re a retailer, distributor, or brand owner, we offer the best merino wool socks tailored to your needs.

Contact us today to discuss your OEM & wholesale merino wool socks orders and get a competitive quote.